Polishing Concrete Floors

Polished concrete is a process that makes any concrete slab, old or new, a low maintenance work of art. Polished concrete flooring is achieved by grinding the floor with specialized diamond tooling until the floor develops a shine without the addition of any topical paint.

This process, used exclusively by concrete innovations, produces a finished floor requiring no wax or sealer to maintain its glow. The finish is obtained by using specialized concrete grinding equipment that grinds slowly, hones, and then polishes every inch of the concrete floor to the desired sheen.

During the process, eco-friendly solutions are applied and impregnated into the concrete. The first is a densifier. This not only hardens and dust proofs the surface. We can take it a step further and apply our exclusive stain protection, that actually penetrates into the pores of the concrete. Once completed there is no topical sealer or coating on the surface that can scratch, bubble or peel!

The result of the concrete polishing process is a regular piece of concrete transformed into a beautiful flooring system that is more durable, more abrasion resistant, and easier to maintain than your original unpolished concrete floor. All that is required to maintain this highly stain resistant finish is soap and water!

Polished concrete floor will last much longer than carpet, vinyl tiles. The design options are only limited by your imagination. Not only polishing concrete make the floor shiny like a glass, color can be introduced using pigments, dyes and stains both during the pouring of the concrete and after. Decorative saw cuts and logos are all possible with polished concrete.

Concrete polishing is a great choice for facilities that never shut down. All paints and coatings require some dry time after application before they can put back in service. Polished concrete floors can immediately put back in service after completion.

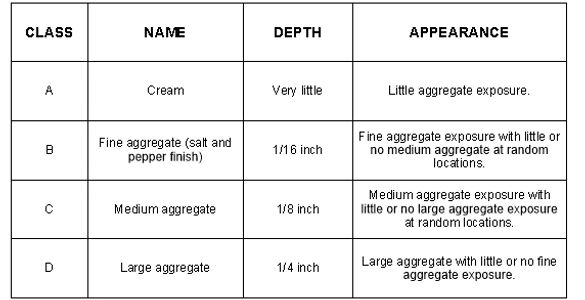

Aggregate and Gloss Tables

Aggregate Exposure Table

Aggregate Exposure Table

Aggregate Exposure Table

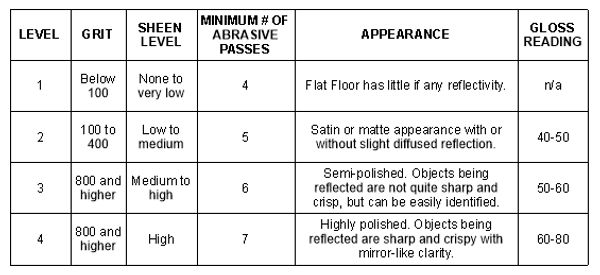

Gloss Level Table

Aggregate Exposure Table

Aggregate Exposure Table

Photo Gallery